Short Cycle Willow Coppice

a fast growing energy crop

I had cause to investigate this recently when we found a large stand of self-seeded willow shoots on our land. They should be ready to harvest this year for the first time and will be used as firewood and to make charcoal and biochar.

This is part of a series of pages on alternative biofuels. Click here to return to the main listing....

Short cycle willow coppice is a modern form of coppicing specifically developed to produce wood for fuel purposes. On a commercial scale large fields of cultivated fast growing willow species are planted in rows for mechanical harvesting, however smaller scale ventures can be quite successful for homesteaders or others living off grid and wanting to become fuel independent. The willow is harvested regularly (usually every 3 years) and hence is referred to as 'short cycle willow coppice' - sweet chestnut coppice is typically harvested every 12 - 15 years.

Cut willow is usually of small diameter, around 1 inch or less so is not usually suitable for burning directly in a traditional wood stove. Typically the stems are left to dry in large stacks in the field, before being chipped.

One chipped they are either burned in large commercial scale wood chip furnaces or processed to make compressed wood pellets.

How is Willow Coppice established?

The productivity of your willow coppice depends heavily on the varieties of willow you end up planting. Modern cultivated willows have different properties - some are resistant to pests, some produce heavier crops, some tolerate drier or wetter soil conditions. When choosing bearing mind that

- Mono-cultures of identical plants tend to be more prone to disease

- Picking varieties appropiate for your soil conditions will improve yield

- Modern cultivars are protected by current patent laws - it is illegal to take cuttings from named varieties while they are protected by law - so you can't just cut a few sticks from the local farmers field, or even from your own crops

- Willow usually prefers damp or boggy ground - if you have a damp patch that isn't useful for other crops it may be perfect for Willow Coppice.

- Willow has fairly invasive roots which can choke drainage ditches - consider placement carefully

- Willow is a tall crop ( 3m plus at time of harvesting) - think about what that will do to your local skyline and investigate if it will need planning permission in your area

Planting and Year 1

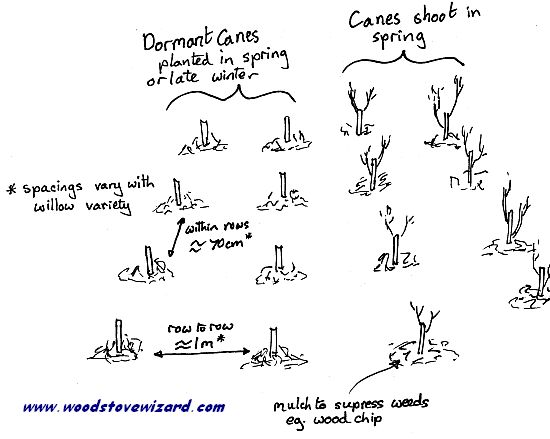

When you have chosen and ordered your varieties they will arrive as long straight willow canes with no growth other than a few dormant buds. These canes can be cut down to 18 inch lengths and pushed for most of their length down into pre-prepared soil. Over the coming spring these dormant canes will shoot with new stems and put out roots.

Commercial spacings have large row separations and short distances within rows (specified by your willow cane supplier). This is to allow for ease of mechanical harvesting. If you are not harvesting mechanically (ie on a smallholding) you might be able to change those spacings to suit your needs. Be aware that productivity estimates are based on commercial spacings - you may adversely affect yield by deviating from these (of course you might also improve on it - I'd love to hear from you if you have had particular success with different spacings).

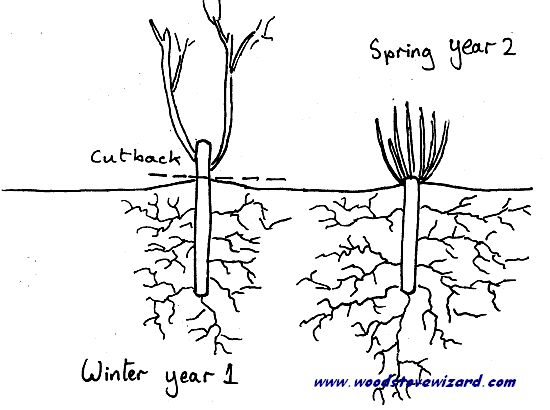

Year 2 - establishment of the willow coppice stool

The 'stool' is the stump and roots from which your future harvests of willow will grow. Once your root system has been established in the first year, and the plant has gone dormant for the winter, you must cut the plant right back down to near ground level. You are unlikely to get any worthwhile fuel in this first year, but cutting the trunk back forces the stool to send up many more straight shoots.

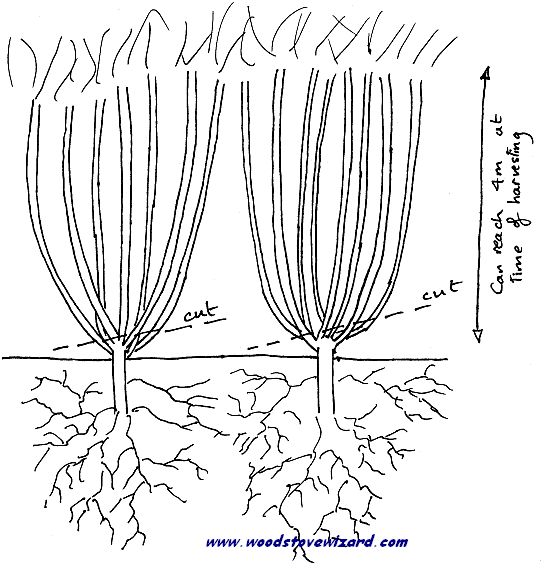

Year 4 - first harvest

In the winter of the fourth year your willow stools should have three years growth on them and be ready for harvesting. Wait until the leaves have fallen and the sap has been drawn back down into the roots in winter. This both helps the plant conserve nutrients for the following seasons growth and reduces the water content in your cut timber reducing the drying time before it is usable.

Use a chainsaw to cut the stems right back down to ground level. Your coppice cycle now starts over as the stool sprouts again in spring.

Handling the harvest

In theory handling a harvest of willow should be relatively straight forward. Simply collect a bundle of cut stems together (a V-shaped bench may help here) and tie around the bunch tightly with string in a few places. Once bound, cut the bundles down to the desired length with your chain saw. If you are intending burn them in a rocket stove, then a bundle with sticks 1m long might be ideal. If you have a wood stove then shorter lengths will be necessary.

The main benefit over traditional timber is that nothing will need splitting and bundled stems can be easily stacked, handled and transported. Twiggy and leafy off-cuts would be ideal to make biochar from.